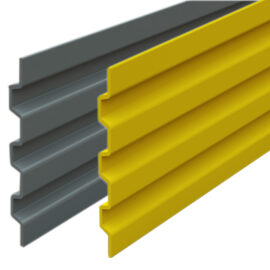

Description

GRP structural profile tubes are all made by the pultrusion process with high glass content and excellent mechanical properties. A corrosion/weathering barrier built into the surface ensures the maximum long-term performance in the most demanding environments. Stocked in 6000mm lengths, we also offer a cutting service – for details click here

- Exceptional strength: on a weight to weight basis, GRP profiles are stronger than structural steel. The excellent impact strength of GRP profiles reduce damage caused by accidental collisions

- Lightweight: weighing up to 80% less than steel and 30% less than aluminium, GRP profiles provide equivalent performance for considerably less weight

- Corrosion resistant: GRP is generally unaffected by exposure to a wide variety of corrosive chemicals and environments. A synthetic surface veil is applied, to provide a resin rich layer, thereby enhancing the already excellent corrosion resistant properties

- Maintenance-free: the corrosion resistant properties of our GRP profiles remove the necessity of periodic painting or surface treatment

- Low thermal conductivity: all of our GRP tube profiles have a low thermal conductivity. For example they are around 1/250 of aluminium, and 1/60 of steel

- Non-conductive: GRP profiles are electrically non-conductive, making their specification ideal for cable trays, ladders, cover boards etc.

- Electromagnetic transparency: GRP is transparent to radio-waves, microwaves and other electromagnetic frequencies. Therefore, GRP tube profiles are ideal for aerial masts and radar applications

- Dimensional stability: GRP is resistant to stretching, warping, or swelling over a wide range of temperatures and physical stresses

- Thermal stability: GRP profiles are capable of withstanding continuous exposure to temperatures of up to 65?C